Laminate flooring can expand and contract according to humidity levels in the room. The last thing you want is for the flooring to significantly expand or contract after it has been installed. This could cause the floor boards to separate or buckle.

There are two types of subfloor – concrete and wood. If your subfloor is concrete then you’ll need a moisture barrier. Moisture barriers prevent any moisture in the concrete subfloor from penetrating your new laminate flooring. If moisture corrupts the core-board it will warp the planks over time.

If your laminate flooring planks don’t come with pre-attached underlay you may want to lay a separate underlay before installing your laminate flooring. This will reduce the noise of foot fall penetrating to the floors below.

It’s time to commence the installation! Before you begin make sure you look over the manufacturer’s installation instructions to familiarise yourself with the steps I’ll be going over in this guide.

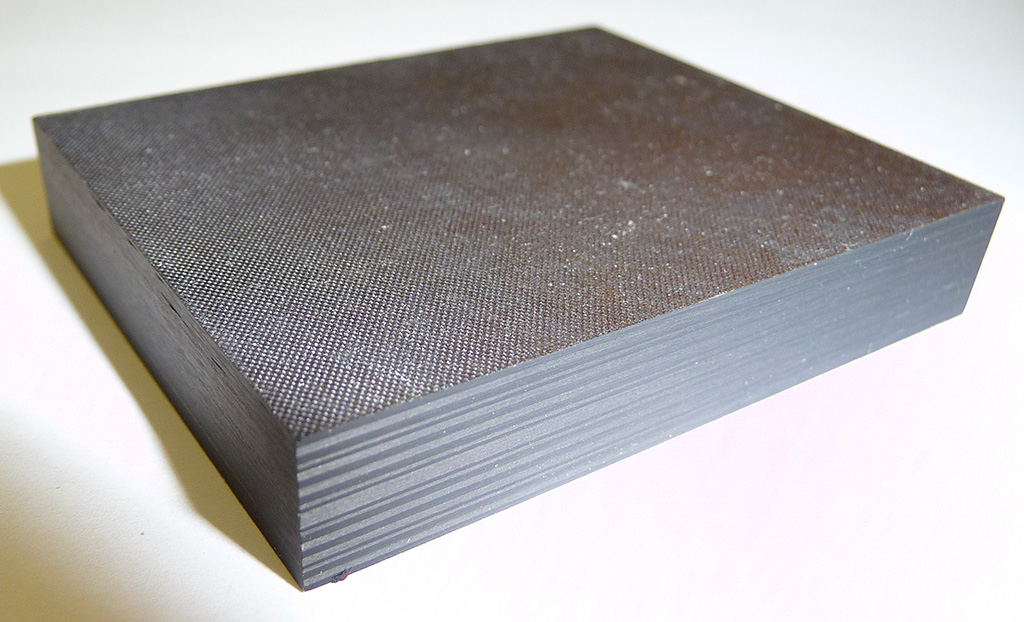

HPLs are the most commonly used laminates. They are comprised of multiple layers of resin-treated paper fused together during manufacturing. HPLs can be adhered to a variety of substrates, have a dimensional behavior similar to wood, and expand and contract with humidity. They are recommended for any application in which durability and impact resistance are concerns, may be used for both vertical and horizontal surfaces, and have a low initial cost and a lifespan of five to 15 years. HPL is also available in hundreds of designs and multiple finishes.

Designing With Laminate

When selecting laminate for a project, there is more to consider than just color and design. Designers must also make a decision on the type of laminate, texture, edge treatments, and substrate or postforming needs. Most often, these decisions are based on performance needs, budget and intended use of the product.

Installation Basics

Laminate is only one of several raw materials used to build a finished product. Laminate must be bonded to a substrate, so adhesives, suitable substrates and backers are required for installation as well. Contact adhesives may be used for bonding laminates to a variety of cores. They are particularly useful for applications to metal or impervious surfaces. Contact adhesives should be uniformly applied to both surfaces that require bonding. These adhesives have high immediate bond strength, and once contact has been made, the components cannot be moved.

There are two primary types of adhesives: solvent-based and water-based. There are many different choices for a substrate, but the best choice is a substrate with high internal bond strength. Unsuitable substrates include plaster, plasterboard, gypsum board and concrete. A backer is then used to balance the laminate construction, prevent warping and protect the substrate from moisture. Backers are generally the same material as the top surface, or one matching in dimensional stability.

The process of heating the HPL to bend around a substrate form is called postforming. Most plastics, once cured in manufacturing, cannot be reheated and reformed, but postforming laminate includes modified resins that allow the sheets to be reformed under heat and pressure. Once heated and formed, the laminate will hold its new shape permanently.

Postforming is used to create countertops, moldings, trim pieces and cabinet doors. It is helpful in places where a “solid” or seamless look is preferred, such as deck edges and cabinet doors, or where “kid-friendly” curves are welcome, since they eliminate sharp edges. Postforming is also used to achieve special edge treatments, laminate inlays or inlays with other materials, such as tile, wood or metal.